3D Reverse Engineering Services

Advenser Engineering Services, since its inception in the year 2007 has always been in the forefront of Digital Construction in the UAE. Digital replicas of physical objects has become critical for businesses aiming to redesign, manufacture, or restore legacy components. Reverse Engineering is used to recreate or reproduce a physical object by capturing its dimensions and geometry through 3D Scanning Techniques, or in simple terms it includes a two-step process – the first step is the scanning of the object while the second step involves creating a 3D model of the object.

How does Advenser’s Expertise help you in your Reverse Engineering Process help you?

Reverse Engineering involves taking existing physical parts and assemblies and creating digital models of the same. Our Scan-to-3D data of physical objects captures intricate details of every object. Our expertise and technology gives us the capability of creating high precision 3D Models of any given object.

- High Precision and Accuracy of the the 3D models generated.

- Adaptability in creating scanned models of both simple and complex physical objects.

- At the heart of everything we do here at Advenser, is Innovation and adapting latest technologies.

- Our highly capable team delivers scanned data in the best possible turn-around-time.

Our 3D Reverse Engineering Services we offer

We use the latest technologies in Scanning to deliver the best results in time.

Scanning

Scanning of Physical objects to create high resolution scanned replicas of them.

3D Modeling Services

Once the scanned model is created, the same is turned into editable CAD Model for redesign or production.

Digital Twin Creation

Developing highly accurate digital replicas of physical objects for analysis and simulation.

Reverse Engineering for Product Design

Assisting with product innovation by reverse-engineering physical prototypes.

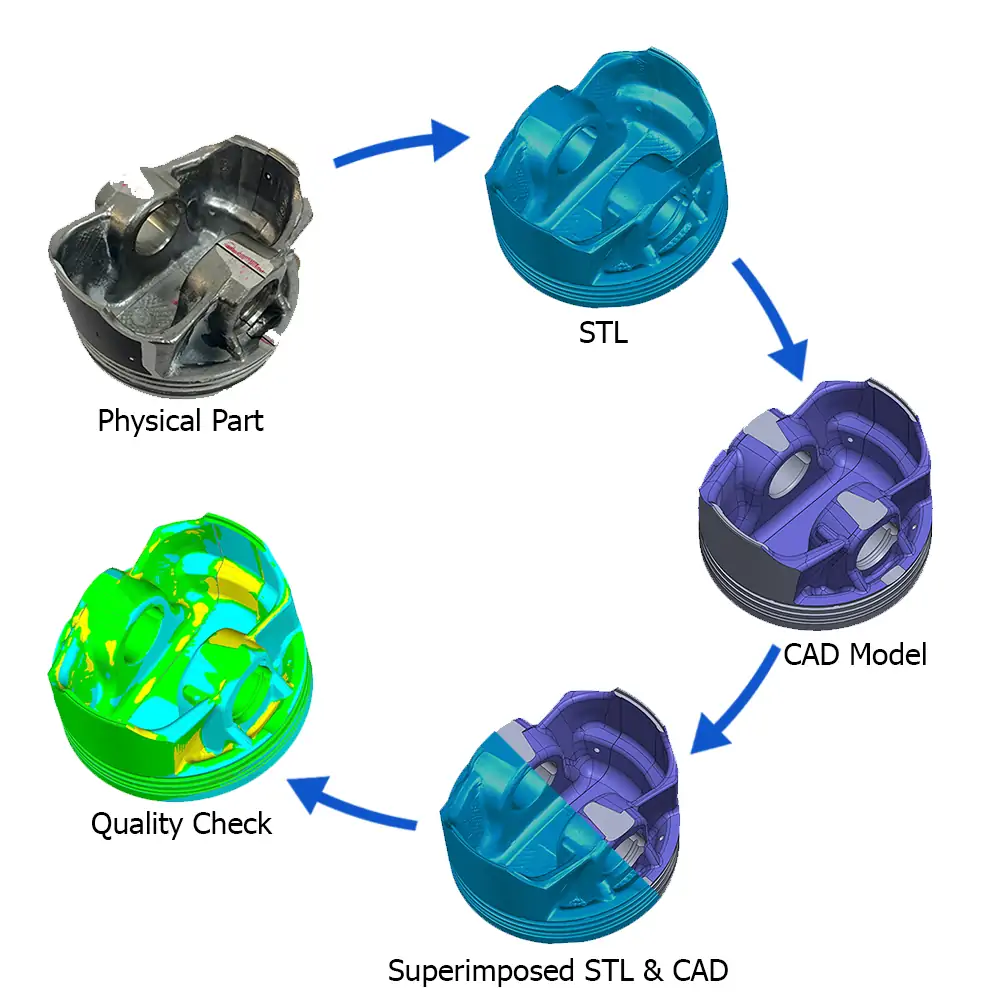

Our 3D Reverse Engineering Process

Utilize our best-in-class Reverse Engineering services, which are designed to transform the existing parts into precise digital model for redesign, analysis, and innovation across industries.

Our 3D Reverse Engineering Process

Our expertise in 3D Reverse Engineering comes from years of experience in using advanced scanning and modeling tools to create precise digital models of physical components, helping businesses with product redesign, accurate replication, and improving existing designs.

- Scanning – In the preliminary stage, a high resolution scan is created of the object.

- STL File – This scanned version of the object is shown in meshed 3D Format.

- CAD Model – The STL file is converted into a refined, editable CAD model.

- Comparison – The superimposed comparison highlights the overlay of STL and CAD Models to check for accuracy.

- Quality Checks – In the figure, we have used colour maps to identify deviations between the STL and CAD models, ensuring precise reproduction.

Our 3D Reverse engineering deliverables

- Point cloud data – color or non-color – PTS, PTX, XYZ

- Polygon models – STL, PLY, OBJ, VRML

- 3D Surface model –IGES, STEP

- Feature based solid model & assemblies – IGES, STEP, ParaSolid, SolidWorks.

- Hybrid CAD model (surfaces and solids) – IGES, STEP, ParaSolid, SolidWorks

- Photo realistic renderings

- Drawings

- Animations

What is Advenser’s Expertise in 3D Reverse Engineering ?

Our expertise in 3D Reverse Engineering comes from years of experience in using advanced scanning and modeling tools to create precise digital models of physical components, helping businesses with product redesign, accurate replication, and improving existing designs.

- Automotive Parts Reverse Engineering

- Aerospace Components Reverse Engineering

- Mechanical Equipment Reverse Engineering

- Injection Molds Reverse Engineering

- Tool and Die Reverse Engineering

- Industrial Equipment Reverse Engineering

- Consumer Product Reverse Engineering

- Medical Device Reverse Engineering

- Quality Control & Inspection Reverse Engineering

- Machinery Wear Assessment & Part Redesign

- Reverse Engineering for Additive Manufacturing

- Custom parts design

- Reverse Engineering for Plant Equipment

- Electrical and Electronic Components Reverse Engineering

- Reverse Engineering for Heritage Restoration

- Marine Component Reverse Engineering

- Power Generation Equipment Reverse Engineering

- HVAC Systems Reverse Engineering

- Reverse Engineering for Electronics Enclosures

- Façade Detailing Reverse Engineering

- Reverse Engineering for Heavy Machinery

- Reverse Engineering for Precision Instruments

- Reverse Engineering for Shipbuilding

- Plant Layout & Facility Reverse Engineering

- Reverse Engineering for Robotics